Laboratory

Our research and development laboratory set up in 2013 constitutes another milestone in the development of the company. The areas

- material selection,

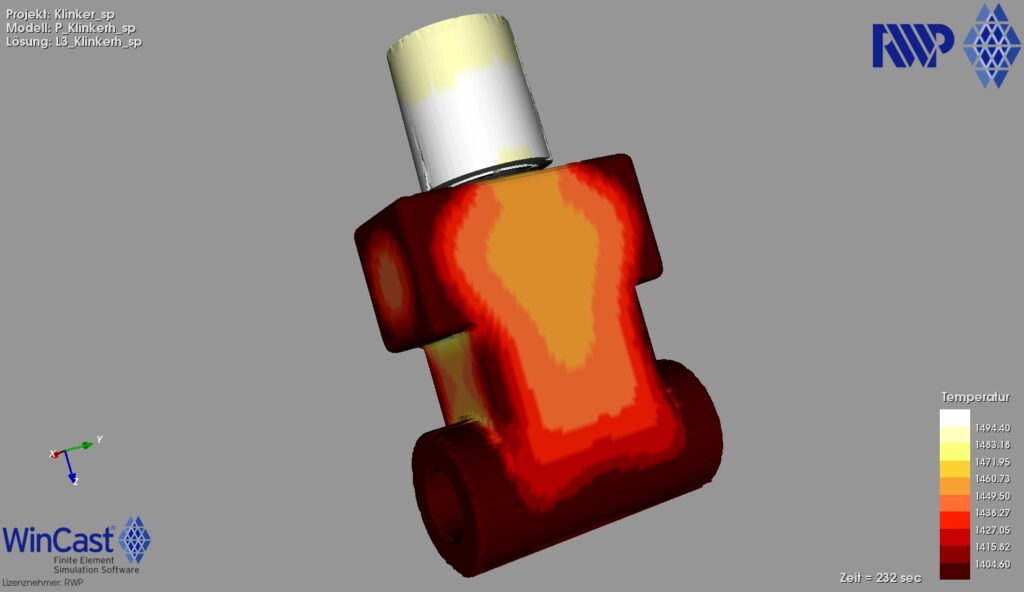

- process selection,

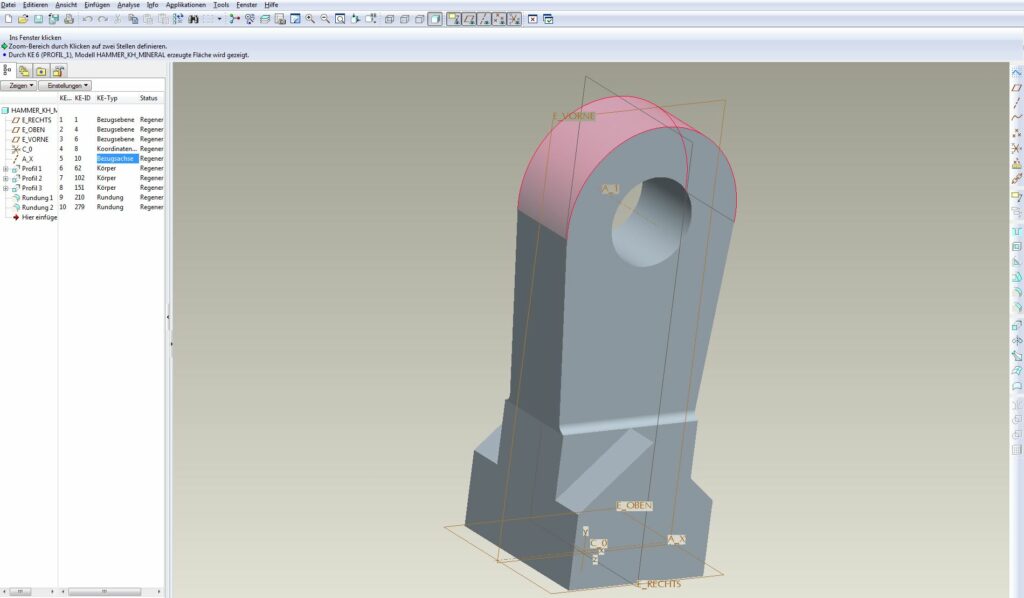

- component design and

- quality management

have been centralised under one roof. The laboratory is to provide the company with innovative power and to create sustainable products as well as new solutions, such as new material combinations or special materials.

State-of-the-art laboratory equipment is available for this purpose, e.g.:

- spectral analysis for determining the chemical composition of materials,

- metallographic and stereo microscopes with digital image processing for the qualitative and quantitative structural analysis,

- stationary and mobile hardness testing equipment,

- ultrasonic testing equipment for assessing the internal properties of castings,

- CAD programs (Pro/ENGINEER) for optimising components,

- surface crack detection (dye penetrant testing, magnet powder testing) and a

- chamber furnace for heat treatment to improve material characteristics and enhance component reliability